Friday, April 26, 2024

Friday, April 26, 2024  Friday, April 26, 2024

Friday, April 26, 2024

For over a century, steel rebar has been the go-to material to reinforce concrete but a new approach promises to make the common building material stronger and more environmentally friendly. Scientists have leveraged 3D printing to produce a polymer lattice structure that can act as the backbone for low-carbon concrete that also boasts great strength and durability.

The research was conducted at the University of California, Berkeley and builds on previous efforts to reinforce concrete using polymer fibers. This emerged around half a century ago as a promising alternative to steel rebar reinforcements, which offer great strength but are heavy, expensive and degrade over time.

Polymer fibers, on the other hand, are lightweight, cheap to produce and are resistant to corrosion. Current approaches involve mixing these fibers into the concrete before it is poured, but this can lead to an uneven distribution meaning some parts of the final structure are stronger and others are susceptible to cracks.

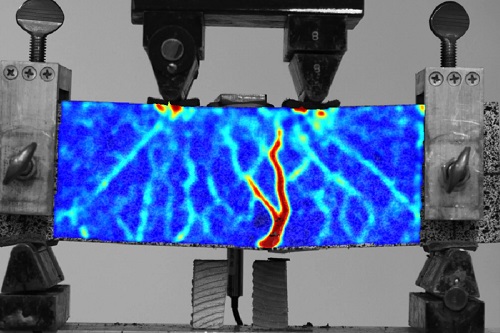

The engineers behind this new study sought to address this shortcoming with a 3D-printed octet polymer lattice, a structure favored for its unique combination of lightness and strength, and one hoped to prevent cracks from forming through a dense arrangement of trusses. The team found success using acrylonitrile butadiene styrene (ABS) polymers to produce the lattice, with the gaps then filled with ultra-high-performance concrete, which is four times stronger than regular concrete in terms of compression.