Friday, July 26, 2024

Friday, July 26, 2024  Friday, July 26, 2024

Friday, July 26, 2024

Got news? Next submission deadline is Friday at 5:00 p.m.

Click here to submit YOUR news

There’s a building material that could keep houses intact during hurricanes, earthquakes, tornadoes and fires. While it’s been widely used around the world, the U.S. is a laggard in adopting the construction technique.

One company trying to change that is RSG 3-D, which is bringing a building material known as 3D cementitious sandwich panel for mass production in the U.S.

“Housing economists will tell you that 77 percent of homes built in the United States are at extreme risk for some type of natural disaster,” said RSG 3-D CEO Ken Calligar. “The East Coast is primarily hurricane, the Midwest is tornadoes, which we will also survive, the Rockies and the West are wildfire plus seismic events. We are resistant to all of that.”

Last year was the costliest year on record for climate disasters in the U.S., with over $300 billion in damages, according to NOAA.

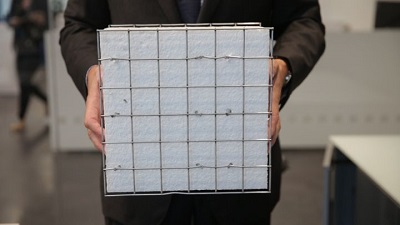

Each panel made by RSG 3-D consists of fire retardant foam sandwiched between two wire mesh faces. The two faces are connected with reinforcement wires that run through the foam and the whole thing is enveloped in concrete.

“The RSG 3-D panel is known for it resilience to natural disaster,” Calligar said. “The panels are fireproof, they are seismic resistant beyond any earthquake recorded in human history and they are also hurricane resistant. They’ve been tested throughout the world through 200 hurricanes, hundreds of seismic events and several wildfires.”

The technology is not new. NASA has been using a version of it to build spacecraft for years because of its strength. And former President Carter used the material through his charity work for rehabilitation efforts decades ago on damaged buildings in Florida and Georgia.

“One of the major push for that technology actually was the adoption of that system by our former President Carter,” said Ayman Mossallam, a civil and engineering professor at the University of California, Irvine.

Carter’s use of the sandwich panels drew attention to the technology, but it was not clear at the time how to manufacture it on a large scale. A company in Austria called EVG cracked the code and created machines to assemble the panels, bringing down the costs of manufacturing.

Watch our video and learn more about the benefits of joining Construction Links Network – the peer-to-peer network sharing platform for the construction, building and design community.

Press Releases | Project Updates | New Appointments | Awards & Milestones | Company News | New Products/Services | Brochures | Videos | Infographics | Blog Sharing | Events and More