Wednesday, October 2, 2024

Wednesday, October 2, 2024  Wednesday, October 2, 2024

Wednesday, October 2, 2024

A Review of Wired and Wireless Temperature and Strength Concrete Sensors

In a construction project, concrete is often on the critical path. Most of the jobsite activities can not be initiated unless the concrete that is placed for building structural elements such as beams and slabs has achieved sufficient strength (typically 75% of the specified compressive strength of concrete). If concrete is not cured properly in favorable temperature ranges (at least more than 5°C or 40°F based on ACI 306) after pouring, it is quite possible to have a slippage in the project plan and timeline due to the delayed strength development in concrete. Curing temperature is also important when it comes to mass concrete placements such as foundations. If the temperature differential between the surface and core of the mass concrete element exceeds a certain level, there is good chance of concrete cracking due to thermal stresses. Project managers, therefore, have a thermal control plan to ensure that concrete achieves the target strength values as scheduled during the first few days after pouring concrete so they can safely move to the next steps of construction such as formwork removal or post-tensioning with confidence.

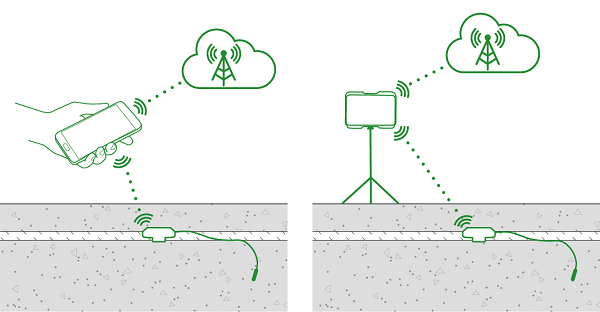

A comprehensive thermal control plan describes the temperature monitoring procedure that the general contractor or concrete sub-contractor must implement when placing concrete in cold or hot weather conditions, as well as that for mass concrete elements. This plan generally includes details on the minimum and maximum allowable temperature values for different structural locations, maximum allowable temperature differential for mass concrete placements, type of equipment, sensors and tools for temperature measurement, frequency and duration of temperature readings, as well as relevant heating or cooling producers.

The in-situ concrete temperature measurements can also be used to estimate the strength of concrete using the maturity method (as per ASTM C1074) in real-time. The possibility of obtaining field strength of concrete (without relying of delayed lab test results), makes concrete temperature measurement even more important particularly in structural concrete elements. In addition to temperature measurement that is an essential part of every thermal control plan, some contractors have been leveraging the maturity method to optimize their project schedules and prevent delays in critical construction operations such as stripping forms, shoring and re-shoring removal, pulling post-tension cables, and opening traffic on concrete pavement. In addition, the simultaneous monitoring of concrete temperature and strength provides opportunities for the optimization of heating and cooling cost, as well as allowing for higher temperature differentials.

Keep reading this blog on Giatec.ca

Check out the video gallery here