Thursday, April 25, 2024

Thursday, April 25, 2024  Thursday, April 25, 2024

Thursday, April 25, 2024

Temperature and maturity monitoring of cold weather concrete is required in most cold-weather concreting applications and is essential to identifying the potential for freezing and thermal shock, optimizing curing, and ensuring safety of a structure.

When placing concrete in cold weather, extra precautions must be taken to ensure that the concrete sets properly and gains adequate strength. The first few days after placement are the most important because that is when the cement hydration reaction proceeds the fastest and the concrete gains most of its overall strength. However, cold temperatures slow the hydration process, meaning that concrete placed in low temperatures gains less strength than the same mix in warmer temperatures during the same length of time. If the water in the concrete mix freezes, the hydration process stops completely. Even if it thaws, strength gain may not recover.

Therefore, regulating the temperature of concrete in cold weather is essential to its proper strength development. The American Concrete Institute (ACI) specifies in ACI 306R-16 Guide to Cold Weather Concreting recommended concrete temperatures based on the air temperature. It recommends a minimum temperature during placement, minimum temperature at mixing, and maximum allowable gradual temperature drop within 24 hours after the end of protection from the cold weather. These recommendations are often mirrored as requirements in job specifications.

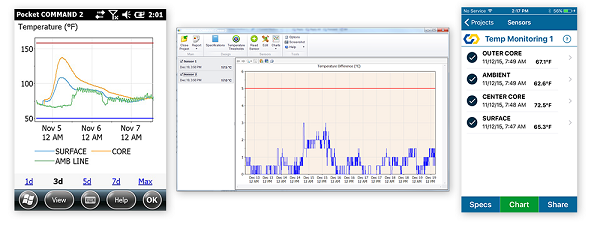

To ensure the internal temperature of concrete does not drop below freezing and is within specified requirements per ACI and/or project specifications, sensors can be embedded in the concrete to continuously monitor and record concrete temperature at regular intervals. This data informs the user of the concrete’s temperature history, so the user can verify compliance with project specifications.

There are three primary reasons that temperature monitoring is used by contractors in cold weather concrete placements: