Saturday, September 28, 2024

Saturday, September 28, 2024  Saturday, September 28, 2024

Saturday, September 28, 2024

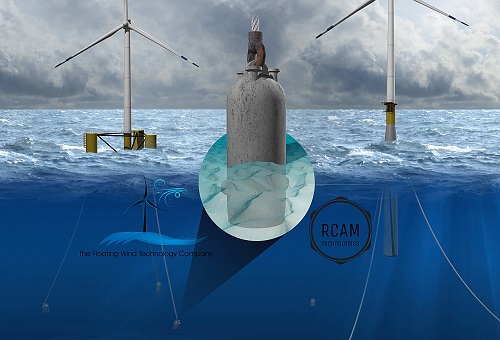

Wind off the coasts of the U.S. could be used to generate more than double the combined electricity capacity of all the nation’s electric power plants, reports have suggested.

But building wind turbines offshore is expensive, requiring parts to be shipped at least 30 miles away from a coast.

Purdue University engineers are conducting research on a way to make these parts out of 3D-printed concrete, a less expensive material that would also allow parts to float to a site from an onshore plant.

“One of the current materials used to manufacture anchors for floating wind turbines is steel,” said Pablo Zavattieri, a professor in Purdue’s Lyles School of Civil Engineering. “However, finished steel structures are much more expensive than concrete.”

Conventional concrete manufacturing methods also require a mold to shape the concrete into the desired structure, which adds to costs and limits design possibilities. 3D-printing would eliminate the expenses of this mold.

The researchers are working in collaboration with RCAM Technologies, a startup founded to develop concrete additive manufacturing for onshore and offshore wind energy technology, and the Floating Wind Technology Company (FWTC). RCAM Technologies and the FWTC have an interest in building 3D-printed concrete structures including wind turbine towers and anchors.

“Purdue’s world-class capabilities and facilities will help us develop these products for offshore products for the U.S. Great Lakes, coastal and international markets,” said Jason Cotrell, CEO of RCAM Technologies. “Our industry also needs universities such as Purdue to provide the top-quality university students for our workforce needs for these cutting-edge technologies.”

The work also is funded by the National Science Foundation INTERN program.

Check out the video gallery here