Friday, October 4, 2024

Friday, October 4, 2024  Friday, October 4, 2024

Friday, October 4, 2024

Lead remains the most commonly used material for radiation shielding but its toxicity is one of its major drawbacks. There has been significant advancement in the development of non-lead shielding material for the radiation shielding industry. Innovations have focused on producing thinner, more flexible, and effective non-lead shielding. Specifically, polymers are being utilized for their material properties and infused with tungsten and other metals to produce a new generation of shielding products.

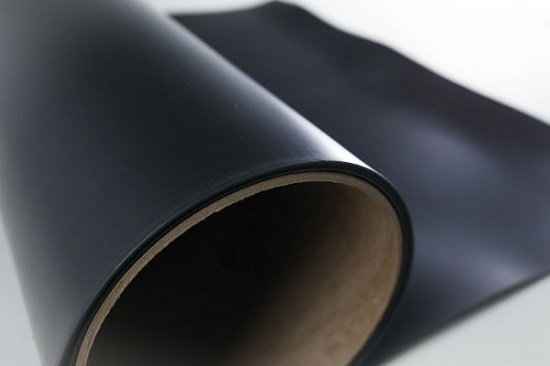

Non-lead alternatives come in a variety of forms. The main sheet form is metal impregnated polymers which are a polymer that contains a shielding material. This capitalizes on the shielding properties of the metal, and the flexibility of the polymer.

The composition of these materials can vary depending on the product but generally, a polymer base is used for the product. Materials, such as metals and non-lead, high atomic numbered elements are added for shielding including Tungsten, Bismuth, and Iron. The percentage of these materials can vary anywhere from 0-95% of the material depending on the product. In addition, to improve the material properties, other materials like glass and carbon fibers are also in the material.

Keep reading this blog on Marshield.com