Saturday, October 5, 2024

Saturday, October 5, 2024  Saturday, October 5, 2024

Saturday, October 5, 2024

There are more than a few enchanting places to see in Paris that do not include the city’s iconic Eiffel Tower. However, her omnipresence in peoples imagination is inevitable.

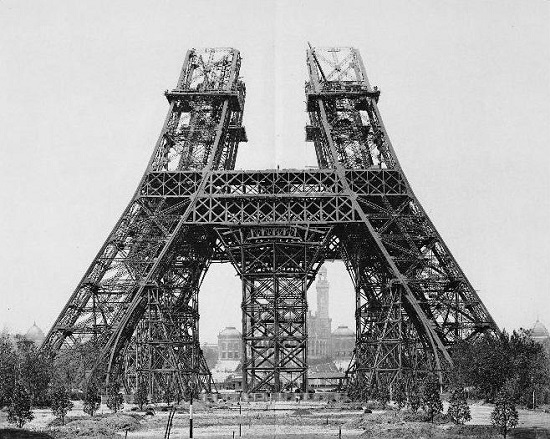

A cultural icon of France, the Eiffel Tower is locally dubbed “La dame de fer” (French for “Iron Lady”) and was constructed at the end of the 19th-century. It was purposed as the entrance to the 1889 World Fair.

At the time of its construction, French intellectuals and artists criticized the design of the tower. And perhaps to their disbelief, the Eiffel Tower became the most recognizable structure in France and maybe all of Europe. With almost 7 million people ascending it in 2015, the tower eventually became the most visited cultural monument globally, which requires an entrance fee to enter.

Contrary to some assumptions, the Eiffel Tower is not made of steel. It’s made of high-grade iron, forged in eastern France. The tower’s iron plates and beams were then puddled and preassembled in the Eiffel factories on the outskirts of Paris.

Work on the tower officially began on January 26th, 1887. First, a foundation was dug, which took four months of work. Then construction continued to add the floors.

The tower construction used 18,000 pieces to assemble. Engineers meticulously calculated how each piece was going to fit the structure. The ironworks were assembled on-site by using bolts, and were later one by one replaced with temperature-sensitive rivets, which contracted during cooling, securing structural integrity.

The builders hired for the Eiffel construction effort were experienced in great metal viaduct projects. Four men had to work on each rivet to assemble. One person needed to heat the rivet, a second to hold it in place, and two more men to shape the head and beat it with a sledgehammer.

Keep reading on ThisCityKnows.com