Friday, April 19, 2024

Friday, April 19, 2024  Friday, April 19, 2024

Friday, April 19, 2024

As blogged on New Atlas, a German research team has prototyped an extraordinary heating/cooling system that stresses and unloads nickel-titanium “muscle wires” to create heated and cooled air at twice the efficiency of a heat pump or three times the efficiency of an air conditioner. Crucially, the device also uses no refrigerant gases, meaning it’s a much more environmentally friendly way to heat or cool a space.

The device is based on a peculiar property of certain shape-memory metal alloys that spring back into shape after being deformed. In some cases – particularly with nickel-titanium, also known as nitinol – these metals absorb significant amounts of heat when they’re bent out of shape, and then release that heat when they’re allowed to revert to their normal shape. The difference between the loaded wire and the released wire can be as much as 20° C (36° F).

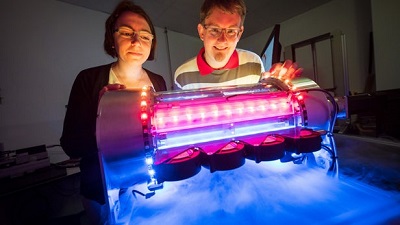

The cooling device is thus quite simple in concept. It uses a rotating cylinder covered in nitinol wire bundles. The wires are loaded up as they pass through one side, sucking heat out of the air and storing it up. Then as they rotate past the other side, they’re allowed to snap back into shape, dumping the heat on the second side. Air is blown through chambers on each side, giving you one feed of heated air and another feed of cool air.

The Saarland University team has been experimenting with the device to figure out the optimal convergence of wire loading, rotational speed, and how many wires should be in a bundle to create the biggest possible heat differential between the two sides from a given energy input.

And the results seem very exciting. The Saarland University team claims that “the heating or cooling power of the system is up to thirty times greater than the mechanical power required to load and unload the alloy wire bundles” depending on the type of alloy used. They say that this makes their new system more than twice as good as a conventional heat pump and three times as good as a conventional refrigerator.

Watch the video and learn more about Construction Links Network – the peer-to-peer network sharing platform for the construction, building and design community.

Ideal for YOUR Press Releases | Project Updates | New Appointments | Awards & Milestones | Company News | New Products/Services | Brochures | Videos | Infographics | Blog Sharing | Events and More